caTEGORIES

Tags

Why Are Machine Screws Essential in Precision Engineering?

Posted: October 10, 2024

Categories: News

In the precision engineering industry domain machines screws are significant, for providing fastening solutions due to their sizes and threading features They enhance the stability and dependability of various applications In environments that require accuracy machine screws aid in maintaining the integrity of assemblies ensuring equipment performance The significance of machine screws, in engineering tasks is truly invaluable

Significance of Machine Screws in Precision Engineering

Contribution to Precision and Accuracy

Crafted machine screws are designed with threading that aligns seamlessly with corresponding components, for a perfect fitment every time. They offer enhanced tolerances that ensure a connection with nuts or threaded holes compared to screws. In fields, like precision engineering where minor variations can cause issues the accuracy of machine screws plays a pivotal role. Besides this type of screws minimizes the chances of thread damage making sure that assemblies remain secure over time.

Versatility in Material Compatibility

Machine screws are highly adaptable because they can be used with materials such, as steel and aluminum. This versatility makes them valuable in industries like consumer electronics and heavy machinery due to their ability to resist corrosion and their lightweight nature which is ideal, for aerospace applications.

Durability and Reliability Factors

Strength and reliability are factors, in engineering tasks; machine screws excel in meeting these criteria admirably! Their robust construction allows them to withstand challenges like varying temperatures and vibrations with steadfastness unlike screws that are prone to wear and tear resulting in failures, over time; machine screws are crafted meticulously to ensure prolonged resilience is maintained consistently. This dependability proves vital in situations where safety and performance hold importance; by choosing high-quality machine screws engineers can trust in the effectiveness of their designs.

Comparing Machine Screws to Regular Screws

Comparing machine screws, to screws reveals that their differences affect their performance and the specific applications they are suited for; understanding these distinctions is crucial when selecting the parts.

Design Differences

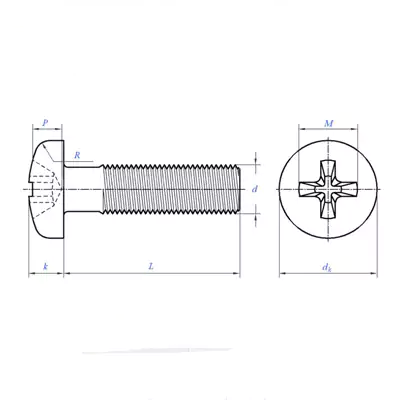

There is a difference, in the threading patterns between machine screws and standard screws to consider when designing them; Machine screws have threads that are designed to be used with tapped holes or nuts specifically; meanwhile, standard screws often have thread patterns based on their intended use which may lead to differences, in compatibility and usability levels. It is also common for machine screws to have a head size to ensure a fit and improve the overall look of the final products.

Performance Under Stress

When faced with conditions such, as pressure or strain on them machine screws distinguish themselves from screws due to their distinct design and materials utilized in manufacturing them which enable them to bear heavy loads effectively. Conversely, regular screws may not fare well in situations leading to project delays or safety hazards. In fields like the construction of bridges or advancement, in aerospace technology the capacity of machine screws to endure forces without deformation holds significance.

Application-Specific Uses

In fields such, as engineering and aerospace where precision’s essential, for projects Machine screws are preferred over standard household screws for their durability and capability to meet the specific needs of complex engineering tasks.

It’s a moment to acknowledge Qewit as an established manufacturer of fasteners such, as machine screws that are designed to meet precise engineering standards. Qewit Fasteners provides a variety of machine screws in materials and sizes tailored for uses across industries. With an emphasis on quality and precision Qewit has emerged as an option, for engineers seeking fastening solutions. They offer a product line equipped with features that cater to customers’ specific needs while guaranteeing top-notch performance and durability.

Industry Innovations and Qewit’s Role

Technological Advances in Screw Manufacturing

The production of machine screws has seen changes, in the few years due to technological advancements and developments in materials science. The use of cutting-edge machining techniques like CNC (Computer Numerical Control) technology has improved the accuracy of screw manufacturing. This results in machine screws being made with tolerances and more uniformity than, in the past. Additionally, the incorporation of materials has allowed for the development of screws that provide strength and resilience enabling their use across a wide range of industries.

To these advancements and progressions, in technology, the implementation of automation within the manufacturing process has enabled producers to enhance productivity cut down on waste, and decrease manufacturing expenses. These kinds of advancements favor consumers directly by offering notch-cost fastening options. These aspects have established machine screws as a component of engineering methodologies given that their dependability and efficacy, in challenging circumstances, are consistently enhanced. In the changing landscape of industries and technologies improving continuously in the domain of screw production is expected to result in the development of tailored fastening solutions catering to the requirements of precision engineering experts.

Qewit Fastener Company Overview

Qewit Fasteners is recognized as a producer of machine screws and various accurate fastening options, in the fastener market field. Having experience spanning decades Qewit commits to offering solutions that fulfill the strict needs of precise engineering uses. The business takes pride in its utilization of cutting-edge manufacturing technologies that allow for the creation of a selection of machine screws tailored to specifications and demands.

Quality is highly valued at Qewit above all else.In order to uphold this standard the company enforces quality control procedures at every stage of production to guarantee that each item meets or surpasses the set performance and durability benchmarks. This dedication, to quality has established Qewit as a vendor trusted by both engineers and manufacturers. Always striving for improvement, through research and development efforts Qewit continues to lead in innovative fastener manufacturing techniques to keep its product line aligned with the demands of the market.

Unique Offerings by Qewit

Qewit’s product portfolio is designed to offer versatile fastening solutions catering to various industries. Among its extensive selection, you will find machine screws in a multitude of sizes, designs, and materials. This includes options in stainless steel, brass, and specialized coatings that grant additional properties, such as corrosion resistance or enhanced strength. Such diversity allows engineers to select the most appropriate screws for their specific applications, thereby enhancing performance and reliability.

Furthermore, Qewit offers custom solutions, recognizing that precision engineering projects often require unique specifications. The company’s ability to tailor machine screws according to client needs, including specific lengths, threads, and materials, enables engineers to achieve optimum performance in their applications. This customer-centric approach solidifies Qewit’s position as a vital partner in the engineering and manufacturing sectors, as they work diligently to ensure that clients have access to the right fastening solutions for their projects. In summary, the role of machine screws in precision engineering is underscored by innovations in their manufacturing processes. The advancements in technology not only contribute to the quality and reliability of these components but also enable manufacturers such as Qewit to meet the varied demands of the industry effectively. Through rigorous quality control, a diverse and customizable product offering, and a commitment to innovation, Qewit stands ready to support engineers as they tackle the challenges of modern precision engineering.