caTEGORIES

Tags

Why Are Button Head Bolts Critical in Precision Engineering

Posted: September 26, 2024

Categories: News

Understanding Button Head Bolts

Definition and Characteristics

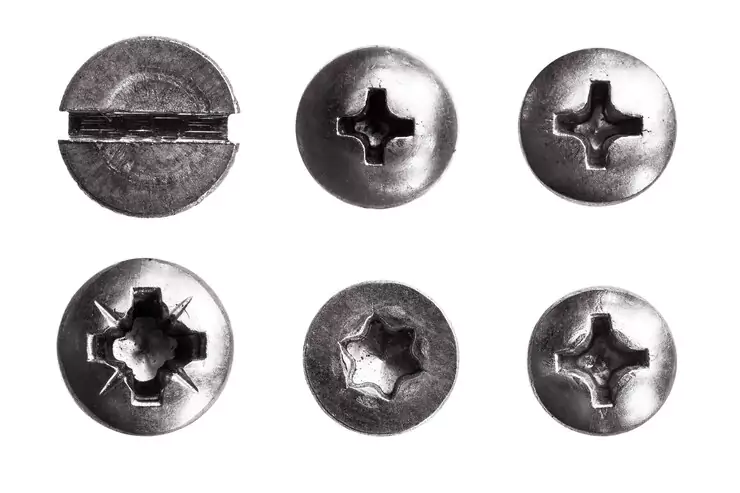

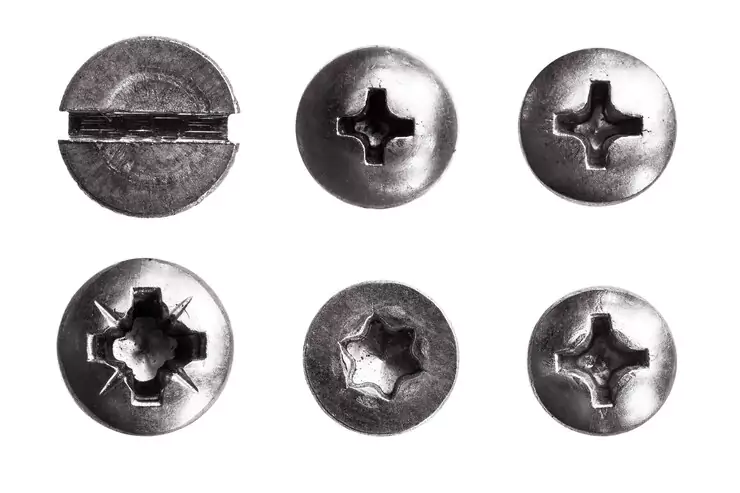

Button head bolts are fasteners known for their heads, which resemble domes in shape. This specific design enables them to have a surface area, for load distribution when securing components together. Additionally, the smooth curvature of the button head helps reduce the chances of snagging which can be especially advantageous in situations where maintaining a surface finish is crucial. These bolts come in sizes and materials. Usually comes with either a hex or socket drive, for convenient installation and removal.

Material Composition and Durability

Button head bolts are made from materials such, as carbon steel stainless steel, and brass for purposes including improving their strength and performance qualities Each type of metal has its own special features that help to make the bolt last longer and perform better For example stainless steel is particularly good at resisting corrosion making it ideal for outdoor or humid conditions The selection of the right materials and coatings is crucial, in ensuring that button head bolts can withstand tough conditions and last a long time

Comparative Analysis with Other Bolt Types

Button head bolts provide benefits compared to hex head bolts, in engineering applications. Their sleek design enhances the appeal of precision equipment where aesthetics play a role. Moreover, button head bolts typically need more force to install than hex head bolts reducing the likelihood of threads. The customization options for length and thread type make button head bolts versatile, for engineering needs.

The Role of Button Head Bolts in Precision Engineering

Essential Applications in High-Tech Industries

Button head bolts are widely used in precision engineering across industries such, as aerospace and automotive as well as in electronics applications due to their unique design that enables easy assembly in tight spaces where traditional bolts may not be suitable. For instance, in the field of aerospace engineering weight reduction is crucial and employing button head bolts can enhance efficiency and maintain the strength of aircraft components.

Benefits: Strength, Reliability, and Aesthetic Appeal

Button head bolts are renowned for their durability and dependability, in applications where strength is crucially important. They are designed to endure loads and pressures while also adding a touch of elegance with their sleek appearance. This makes them a popular choice in industries that value both performance and visual appeal a trend that continues to rise as businesses seek the blend of functionality and style, in their assemblies.

At the forefront of the industry is Qewit‘s production of top-notch button head bolts that cater to the requirements of precision engineers. With a dedication, to quality outcomes, Qewit delivers products that align with industry benchmarks enabling clients to acquire trustworthy fastening solutions. Their assortment includes button head bolts made from premium materials crafted to excel in challenging scenarios. Thanks to their manufacturing methods Qewit assures longevity and accuracy, in each fastener they manufacture.

Qewit doesn’t just focus on button head bolts; they have expertise in a range of fasteners like pan head recessed machine screws and hexagon head bolts as well. Their pan head screws are made according to DIN 7985 specifications. Come in sizes from M3 to M10 with lengths ranging from 4 to 100 mm. These screws are manufactured using materials such, as steel and stainless steel to guarantee top-notch performance in conditions. At Qewit you can find hexagon head bolts that meet the DIN 931 standards and are designed to be used in settings, with different grades and finishes to choose from.

Choosing the fastener is crucial, for precision engineering experts as it can significantly impact the outcome of the success of a project. Qewit is widely recognized as a trusted companion, for professionals seeking top-notch button head bolts and other specialized fasteners to meet the exacting standards required by their designs.

Qewit offers a range of products to ensure customers can discover the fasteners, for their individual requirements. Whether they prioritize the strength of zinc-plated or brass choices or prefer the flexibility of different sizes available. With a dedication to ensuring customer happiness and quality assurance through checks on every order placed with them in place, Qewit stands out as a respected figure, in the fastener sector.

In summary, the significance of button head bolts, in precision engineering should not be underestimated The distinct design durable material choices and aesthetic advantages render them an essential element that the advanced technology sector depends on Firms such as Qewit are committed to crafting dependable and top-notch button head bolts ensuring that professionals, in precision engineering, can trust the consistency and effectiveness these fasteners offer in their designs and engineering endeavors

Detailed Examination of Qewit’s Button Head Bolts

State-of-the-Art Manufacturing Processes

Qewit utilizes cutting-edge manufacturing techniques to create button head bolts that meet quality criteria. By employing machinery and procedures Qewit ensures the uniformity and dependability of every fastener made. This careful method does not boost the longevity of the bolts. Also guarantees they meet the exact specifications needed in advanced technology applications. The incorporation of state-of-the-art technologies, during production, enables the crafting of button head bolts engineered for performance, in environments serving a wide range of precision engineering requirements.

Quality Control Measures

Ensuring quality control is a part of Qewit’s approach, to manufacturing operations. The button head bolts produced by Qewit go through testing to ensure compliance with industry benchmarks, like ISO and ASTM standards. This process involves an assessment of characteristics, dimensional precision, and surface texture. By adhering to quality assurance measures Qewit guarantees that its button head bolts are capable of meeting the requirements of users. These efforts contribute to strengthening customer confidence and contentment.

Material Sourcing and Specifications

At Qewit Company is really careful when it comes to sourcing materials, for button head bolts! They work closely with trusted suppliers to get top-notch carbon steel and brass that ensures the bolts are quality. The selection of materials is based on their performance features like resistance to rust and high strength which guarantees that the button head bolts, from Qewit will work reliably in certain conditions. Where failure could be a big deal.

Customization Options for Specific Engineering Needs

In light of the fact that precision engineering frequently necessitates custom solutions, Qewit provides customization choices, for button head bolts to satisfy project needs. This adaptability guarantees that customers can acquire fasteners perfectly suited, for their uses minimizing the chance of utilizing products that may not meet design criteria.

Versatile Designs to Fit Varying Requirements

Qewits button head bolts are not just customizable. Also crafted with versatility, and focus to cater to needs in different industries and applications due to their availability in multiple sizes and designs. Their adaptability makes them user-friendly as they offer engineers a range of options, for tackling assembly tasks effectively during the product development stage.

Integration into Precision Systems

Facilitation of Complex Design Frameworks

Button head bolts have a role, in incorporating design structures into precise engineering ventures. Their rounded top shapes enable the distribution of loads, in assemblies subjected to varying loads and pressures.

Examples of Complex Assemblies

Button head bolts are commonly used in structures, in industries like aerospace and automotive – from aircraft bodies to vehicle engine parts – to provide support for assemblies with multiple components that require precise alignment and structural strength maintenance. They are designed to be used in visually appealing spaces where access may be limited and are highly valuable, for design needs.

Simplifying the Assembly Process

The user-friendly design elements of button head bolts make the assembly process much simpler and more efficient, in practice. Installing them is easier and quicker, than using fasteners since they need force to tighten. Moreover, the rounded shape of their heads minimizes the risk of damaging parts lowering the likelihood of rework and enhancing overall project productivity. Qewits button head bolts offer hassle usability that enhances the assembly process in stressful working conditions.

Enhancing Safety and Compliance Standards

Using button head bolts, from Qewit not strengthen the design integrity. Also meets stringent safety and compliance regulations effectively in industries that prioritize high safety standards, like medical equipment manufacturing and critical machinery installations where the dependability of fasteners plays a crucial role.

Adherence to Regulatory Requirements

The button head bolts, from Qewit are made following industry rules to help clients meet safety standards in their engineering work confidently. By adhering to these regulations engineers can reassure stakeholders that their projects uphold the safety measures. This meticulous attention, to detail, showcases Qewit’s dedication to creating fasteners that uphold the reliability of applications amidst demanding conditions.

Increasing Overall Structural Integrity

Utilizing button head bolts, in the assembly process can greatly improve the stability and strength of products. They are. Built to endure types of mechanical pressures making them essential for ensuring longevity and dependability of the final goods that incorporate them. Opting for top-notch button head bolts from Qewit is key, in reinforcing the end product against malfunctions safeguarding both the efficiency and standing of engineering uses.

To sum it up concisely; button head bolts play a role, in precision engineering due to their design features and durable material properties that offer a wide range of customization options for an engineer’s specific needs and requirements. Qewit takes pride in its dedication to improvement and high standards to deliver button head bolts that cater to the changing demands of the precision engineering sector. Empowering engineers to realize their intricate design visions, with assurance and accuracy.