caTEGORIES

Tags

Understanding Proper Screw Selection for Seismic Zone Applications

Posted: August 15, 2024

Categories: News

Importance of Screw Selection in Seismic Zones

Selecting the right screws for use in seismic zones is crucial for ensuring the safety and integrity of structures subjected to earthquake forces. In seismic zones, buildings must be capable of withstanding significant dynamic forces, which means that the fasteners used, including screws, play a vital role in maintaining structural stability.

Risks of Improper Screw Usage

Improper selection of screws can lead to catastrophic failure of connections under seismic loads. Weak or inappropriate fasteners may not be able to handle the repeated stress and strain experienced during an earthquake, potentially causing the structure to collapse or suffer significant damage. Thus, using the correct screws is essential to ensure that all components remain securely fastened and the overall structural integrity is maintained.

Safety Standards and Regulations to Consider

There are multiple safety standards and regulations that must be adhered to when selecting screws for use in seismic zones. These regulations often specify the types of materials, grades, and coatings that are suitable for seismic applications, thus helping to ensure that structures are built to withstand earthquake forces. For example, standards such as DIN 7985 and DIN 933 provide detailed guidelines on the appropriate screws for various construction needs, emphasizing durability and resistance to environmental factors.

As a formally British wholly owned business, Qewitco has become a most reliable supplier of fine quality Fasteners & Fixings to customers throughout Europe and around the world. With a strong focus on producing and trading premium and consistent quality products, Qewitco has established itself as a trusted name in the industry.

Qewitco offers a wide range of fasteners, including screws, that cater to various needs and requirements. Their competitive product lineup includes fasteners of general grade, high grade, as well as fasteners made of Brass/Copper, Stainless Steel, aluminum, and alloys. With a commitment to quality, Qewitco provides test certificates and ensures professional quality control and traceability for their products.

Types of Screws for Seismic Applications

Wood Screws

Structural Integrity and Load-Bearing Capacity

Wood screws are commonly used in seismic applications where wooden structures are predominant. These screws are designed to provide excellent load-bearing capacity and structural integrity, effectively transferring shear forces across connections. This ensures that wooden components remain securely connected, even under the stress of seismic activity.

Common Use Cases in Construction

Wood screws are frequently utilized in timber frame construction and wooden decking, where they secure beams, joists, and panels. Their effectiveness in creating strong, stable joints makes them ideal for use in earthquake-prone areas, ensuring that wooden structures can absorb and dissipate seismic energy.

Concrete Screws

Durability and Resistance in Seismic Conditions

Concrete screws are specifically designed for anchoring into concrete and masonry. They are known for their durability and resistance to seismic conditions, as they can handle significant loads and stresses. High-grade materials such as stainless steel and carbon steel enhance their ability to withstand the corrosive environment often found in concrete applications.

Application Scenarios and Installation Tips

Concrete screws are commonly used to fasten fixtures, railings, and other structural elements to concrete surfaces. To ensure proper installation, it is essential to drill pilot holes to the exact depth and diameter recommended by the manufacturer. This prevents damage to both the screw and the concrete, providing a secure and lasting connection.

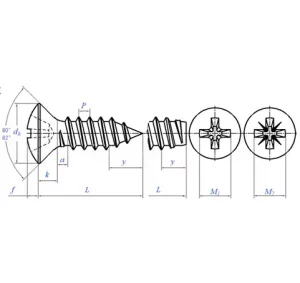

Self-Drilling Screws

Efficiency in High-Stress Environments

Self-drilling screws are particularly useful in high-stress environments, as they do not require pre-drilling and can penetrate metal and other hard materials quickly. This efficiency is crucial in seismic zones where fast and effective fastening is necessary to maintain structural integrity.

Practical Considerations for Builders

When using self-drilling screws, builders must consider factors such as the thickness of materials and the compatibility of the screw with those materials. Ensuring that the correct length and type of self-drilling screws are used will enhance the overall stability and durability of the connections in a seismic zone.

Special Considerations for Using Screws in Seismic Zones

Material Selection Criteria

Selecting the right materials for screws is paramount in seismic zones. Common materials include carbon steel, stainless steel, and brass, each providing different strengths and benefits. It is important to choose materials that offer high tensile strength and resistance to environmental stressors.

Anti-Corrosion Coatings and Treatments

Anti-corrosion coatings, such as zinc plating and zinc flake coatings, are essential for screws used in seismic zones. These coatings protect the fasteners from rust and other forms of corrosion, extending their lifespan and ensuring that they maintain their structural integrity over time.

Load Distribution and Shear Force Management

Effective load distribution and shear force management are critical in seismic applications. The design of the screws must ensure that the loads are evenly distributed across the connection, minimizing the risk of shear failure. Ensuring that the screws are properly installed and appropriately spaced can help achieve this balance.

Factors Affecting Screw Performance in Seismic Zones

Soil and Ground Conditions Impacting Screw Choice

The soil and ground conditions of a construction site can significantly impact the choice of screws. For example, areas with unstable soil may require longer or stronger screws to ensure adequate anchoring. Understanding these conditions helps in selecting the most suitable fastening solutions for seismic resilience.

Building Design and Structural Requirements

Building design and structural requirements also play a crucial role in screw performance. Architects and engineers must consider the specific load-bearing needs and stress points of a building when choosing screws. Properly accounting for these factors ensures that the screws will perform effectively under seismic loads, maintaining the integrity of the entire structure.

Best Practices for Installation in Seismic Zones

Pre-Installation Inspections and Preparations

Before installing screws in seismic zones, comprehensive pre-installation inspections and preparations are crucial. These steps ensure that the site conditions and materials are suitable for seismic resilience. First, examine the structural design and identify areas that will experience the highest stress during an earthquake. Check the soil and ground conditions, as these factors can influence the performance of screws. If the ground is unstable, measures may need to be taken to reinforce the foundations.

Additionally, inspect the materials and tools to be used for installation. Ensure that all screws and related hardware meet the necessary standards and specifications for seismic applications. Conduct a thorough review of the building plans to verify the locations and types of screws required, eliminating any discrepancies that could compromise the integrity of the structure. By performing these meticulous inspections and preparations, builders can enhance the reliability of their installations in seismic environments.

Methods to Ensure Maximum Stability and Security

To achieve maximum stability and security when installing screws in seismic zones, precise techniques and approaches must be employed. One essential method is to use the correct torque when fastening screws. Over-tightening or under-tightening can weaken the connection or damage the materials, reducing the efficacy of the fastening. Utilizing torque wrenches can help achieve the optimal tightness, ensuring a secure fit.

Another critical aspect is to follow the manufacturer’s guidelines and the specific standards such as DIN 7985 and DIN 933. These guidelines provide detailed instructions on the proper installation of screws, including recommended spacing, drilling techniques, and other best practices. Proper spacing is particularly important to distribute loads evenly and avoid concentrated stresses that could lead to failure.

Furthermore, applying the right anti-corrosion treatments before installation can significantly improve the longevity and performance of screws. Coatings such as zinc plating provide a protective layer against rust and environmental wear, which is vital for maintaining the structural integrity over time. Employing high-quality installation tools and methods ensures that the screws perform effectively under seismic conditions, providing durable and reliable connections.

Emerging Trends and Innovations in Screw Technology for Seismic Zones

Advances in Materials Science

The field of materials science has been instrumental in developing advanced screws for seismic zones. Recent innovations have led to the creation of screws that offer enhanced strength, durability, and resistance to environmental factors. For instance, high-tensile grades of steel, such as grade 10.9 and 12.9, provide superior resistance to mechanical stress, making them ideal for seismic applications.

Moreover, composite materials combining metals and other synthetic components are being explored. These composites can offer flexibility and strength, accommodating the dynamic movements experienced during earthquakes. They are engineered to maintain their structural integrity under extreme conditions, providing a reliable fastening solution for seismic zones.

Additionally, advancements in anti-corrosion technologies have resulted in more effective coatings. Innovations such as zinc flake coatings and specialized stainless steel treatments significantly enhance resistance to rust and corrosion. These improvements ensure that screws maintain their performance over extended periods, even in harsh environmental conditions prevalent in seismic regions.

Future Prospects for Improved Safety and Efficiency

Looking ahead, the future of screws in seismic applications promises even greater safety and efficiency. Research and development are focusing on intelligent fasteners equipped with sensors that can monitor tension, stress, and environmental conditions in real-time. These smart screws can provide valuable data on the health of a structure, alerting maintenance teams to potential issues before they become critical, thereby enhancing overall safety.

Furthermore, the integration of machine learning and artificial intelligence (AI) into the construction industry is set to revolutionize screw installation techniques. AI algorithms can optimize the placement and selection of screws based on complex simulations of seismic activity, ensuring that every fastening point contributes to the maximum possible structural resilience.

Energy-absorbing screws and connectors are another area of innovation. These specialized fasteners are designed to absorb and dissipate the energy generated during an earthquake, reducing the stress on the building’s primary structure. By incorporating such advanced technologies, the construction industry can significantly improve the safety and reliability of buildings in seismic zones.

Summary of Key Points on Proper Screw Selection

In summary, the selection and installation of screws for seismic zones are critical components in ensuring the structural integrity and safety of buildings. Proper selection involves choosing high-strength materials that can withstand the dynamic forces of an earthquake, such as those specified in standards like DIN 7985 and DIN 933. Anti-corrosion treatments are essential to protect screws from environmental degradation, thus maintaining their performance over time.

Best practices for installation include thorough pre-installation inspections and precise installation techniques to ensure maximum stability and security. Emerging trends in materials science and technology promise to further enhance the safety and efficiency of screws used in seismic applications. By adhering to these guidelines and leveraging innovative solutions, builders can significantly reduce the risks associated with seismic activity and create safer, more resilient structures.

Partnering with Qewitco means exceptional customer service, technical support, and access to bespoke products. They work exceptionally hard on projects to deliver the best results and provide unparalleled support throughout the process. Whether you need screws for construction, manufacturing, or any other application, Qewitco has the perfect solution for you.

Choose Qewitco for all your fastening needs and experience the difference that their fine quality products and exceptional service can make. With their extensive range of fasteners, commitment to quality assurance, and customer-centric approach, Qewitco is the trusted partner you can rely on. Discover the Qewitco advantage and elevate your fastening experience today.