caTEGORIES

Tags

Nuts Factory QC Crisis: 5 Industry Secrets to Avoid Costly Recalls

Posted: March 20, 2025

Categories: News

Tags: news

The text stresses the vital need to enforce detailed quality assurance strategies in the nut manufacturing sector. This helps prevent expensive recalls and upholds top-notch standards. It describes essential steps like consistent checks and evaluations, tracking mechanisms, and compliance with sector guidelines. The use of sophisticated evaluation methods, such as chemical and bacterial assessments, is emphasized to guarantee product safety and meet health rules. Moreover, the passage highlights how technology boosts the precision and dependability of these quality assurance steps.

Establishing Thorough Quality Assurance Practices

The article notes the practice of preparing a complete quality assurance report near the end of manufacturing. This ensures the batch aligns with the required criteria. It shows a structured method for quality assurance. Products and services are carefully reviewed to match desired benchmarks. The repeated mention of “Quality Assurance” underlines the commitment to sustaining excellent standards throughout production.

Significance of Quality Assurance in Nut Manufacturing

Quality assurance forms the foundation of any thriving nut production business. Without strict quality measures, the chance of recalls due to guideline violations rises sharply. This leads to monetary setbacks. It also harms the company’s reputation. Ensuring every nut meets top quality levels is crucial. This maintains customer confidence and happiness.

Core Quality Assurance Steps in the Nut Sector

Robust quality assurance steps are essential for keeping standards high in nut manufacturing. These steps include:

- Checks and Evaluations: Routine checks and assessments of nuts are vital. They spot flaws or irregularities. This involves visual reviews and advanced evaluation methods.

- Tracking Mechanisms: Using tracking systems lets you monitor each nut batch from production to delivery. It ensures responsibility at every phase.

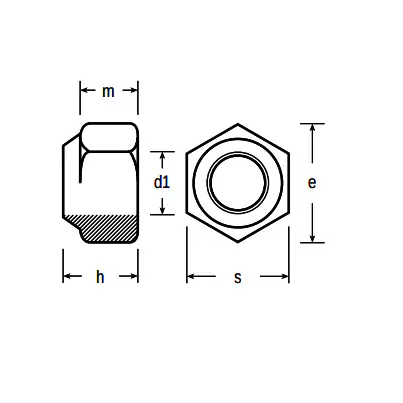

- Guideline Adherence: Following sector benchmarks like DIN 985 or DIN 934 confirms products meet safety and quality specs.

Role of QEWIT Tools in Improving Quality Assurance

Using tailored tools can greatly enhance your quality assurance efforts. For instance, Metric Type T Nylon Insert Nuts DIN 985 resist loosening from vibrations. This is a frequent problem in machinery fasteners. Adding such items to your processes boosts reliability and safety in nut production.

Sophisticated Evaluation Methods for Nut Safety

Advanced evaluation methods are critical for ensuring nut safety and quality. These methods include chemical and bacterial assessments. They detect dangerous substances and bacterial contamination that could threaten safety. Chemical assessments examine nut composition. This ensures they’re free from excessive pesticides or pollutants. Bacterial assessments identify potential foodborne germs.

Chemical and Bacterial Assessment Techniques

Chemical and bacterial assessments are key parts of a thorough quality assurance plan. They help find harmful substances or contamination that might endanger product safety.

- Chemical Assessments: These analyze nut composition. They confirm no dangerous pesticide or pollutant levels exist.

- Bacterial Assessments: Spotting bacterial contamination is crucial to avoid foodborne diseases. Regular bacterial checks maintain safety and health rule compliance.

Using Technology for Precise Outcomes

Cutting-edge technology is vital for accurate assessment results. Automated equipment offers exact measurements. It cuts down on human mistakes. This improves the trustworthiness of your quality assurance efforts.

Advantages of QEWIT’s Tech Solutions

Adopting QEWIT’s tech solutions can simplify your evaluation processes. Their advanced testing setups, like Vision Measurement Projectors and Tensile Strength Testers, ensure every batch meets global standards before shipping. This precision is priceless for preserving product quality and customer satisfaction.

Training Staff on Quality Assurance Rules

Value of Staff Training in Upholding Standards

Staff training is essential for maintaining high quality in nut production. Well-prepared employees are more likely to follow rules. They can also catch potential problems early.

Creating Strong Training Plans

Building effective training plans involves:

- Frequent Seminars: Hold seminars on new tech, sector guidelines, and top practices.

- Practical Sessions: Offer hands-on training. Employees can practice skills under guidance.

- Ongoing Learning: Promote continuous education. Encourage courses or certifications tied to quality assurance.

Using QEWIT Tools for Better Training

Adding QEWIT tools to training gives employees real experience with cutting-edge gear. This sharpens their skills. It also ensures they know the latest tech used in quality assurance.

Enhancing Supply Chain Oversight

Spotting and Reducing Supply Chain Risks

In nut manufacturing, spotting and tackling supply chain risks is key. Risks might include raw material shortages or delivery hurdles. Addressing these proactively prevents costly delays. It ensures steady product flow to customers.

A solid risk management plan requires regular supply chain reviews. Assess supplier dependability, transport paths, and stock levels. After pinpointing risks, create backup plans to handle them quickly.

Ensuring Tracking and Openness

Tracking and openness are crucial for an effective supply chain. Tracking systems let you follow each nut batch from production to delivery. This ensures accountability at all stages. It aids quality maintenance and quick fixes if problems pop up.

Openness means sharing clear details about products and processes with stakeholders. Being upfront about sourcing, manufacturing, and quality steps builds trust with customers and partners.

How QEWIT Solutions Boost Supply Chain Performance

Using QEWIT solutions can greatly improve supply chain performance. Their wide product and service range ensures access to top-quality fasteners and fixings when needed. With over 30,000 product options, you can order multiple items from one source. This boosts efficiency and cuts costs.

Ongoing Enhancement and Innovation in Quality Assurance

Adopting Innovation for Stronger Quality Assurance

Innovation is crucial for better quality assurance in nut production. Embracing new tech and approaches enhances your quality assurance efforts. This could mean using advanced testing gear or automated production monitoring.

QEWIT offers various techniques, from forging and cutting to machining. This flexibility aids production processes. Constantly seeking new solutions keeps you ahead of sector benchmarks. It maintains your competitive edge.

Feedback Cycles and Data Review

Feedback cycles and data review are vital for ongoing enhancement. Gathering data on production aspects helps spot trends and improvement areas. Regularly reviewing this data supports smart choices. It boosts product quality and operational performance.

QEWIT provides technical expertise to assist clients. This ensures they have info to refine operations. Using data insights leads to targeted improvements and better results.

Using QEWIT’s Analytics for Ongoing Enhancement

QEWIT offers advanced analytics tools for continuous improvement. These tools track key performance indicators (KPIs) across operations. They provide insights into areas needing focus.

Integrating these tools into quality assurance increases accuracy in spotting and fixing issues. When customers raise quality concerns, QEWIT’s solutions enable quick responses via re-testing or extra checks.

FAQs

Q1: How do tracking systems help nut manufacturing?

A: Tracking systems ensure responsibility by monitoring each batch from production to delivery.

Q2: What’s the role of innovation in quality assurance?

A: Adopting innovation strengthens quality assurance by using new tech and methods.

Q3: How does data review aid continuous enhancement?

A: Data review spots trends and improvement areas. It supports smart choices to boost quality and performance.