caTEGORIES

Tags

Mastering Threaded Inserts Installation in Metal: Techniques and Tips

Posted: February 18, 2025

Categories: News

Tags: news

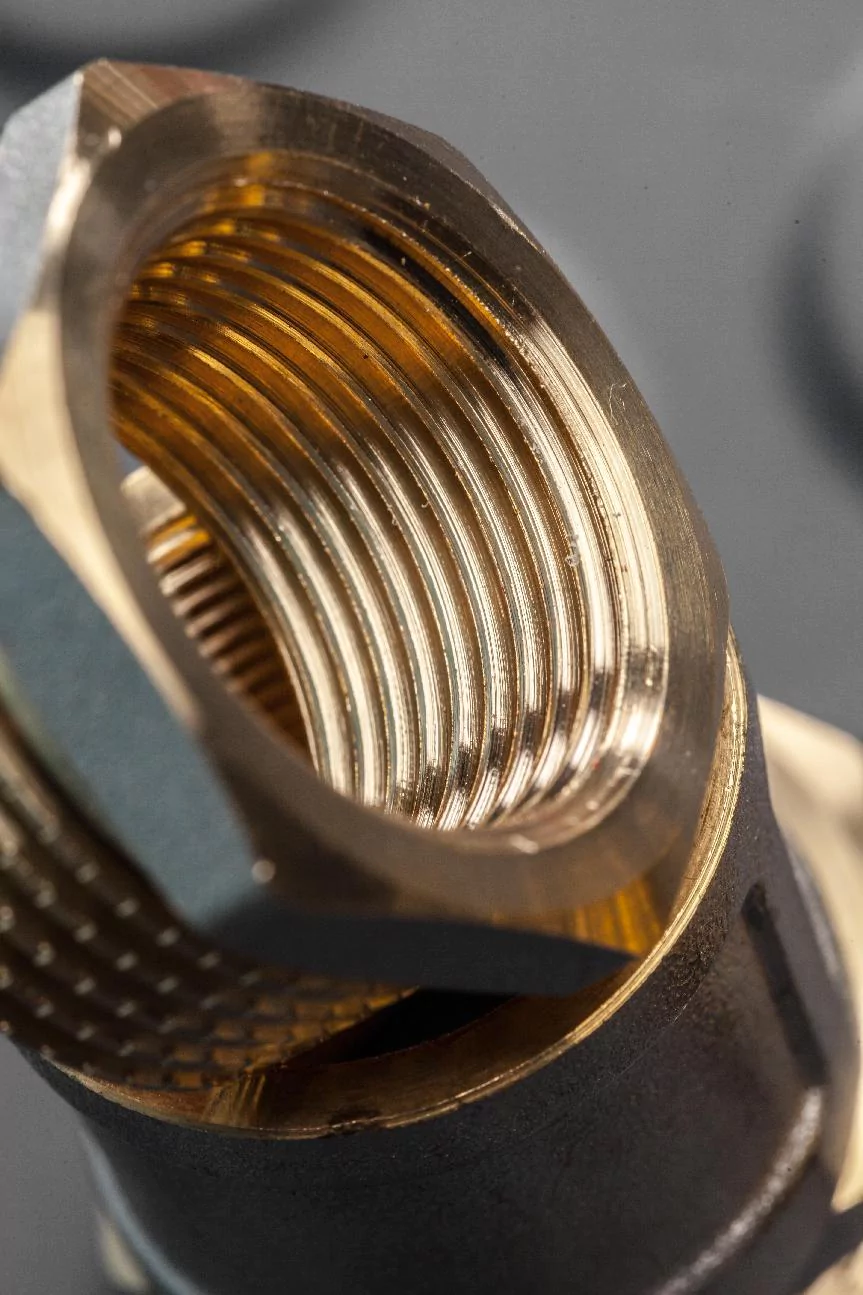

Threaded inserts play a role in metal projects by offering long-lasting and dependable fastener solutions while also providing benefits, like even stress distribution and simplified assembly and disassembly processes to strengthen connections effectively.

Understanding Threaded Inserts in Metal

In sectors and industries using metal materials for fasteners and connections, threaded inserts play a crucial role by offering long-lasting and dependable fastener options. These inserts are crafted to establish a reusable thread in metal surfaces, bringing notable benefits compared to conventional fastener techniques.

Types of Threaded Inserts

In metal applications, different types of threaded inserts serve functions. Some common varieties are inserts, which offer great resistance to vibration with their coiled wire design; solid threaded inserts suited for heavy-duty tasks due to their strong build; and self-tapping inserts that can create threads during installation, removing the necessity for pre-tapped holes.

Benefits of Using Threaded Inserts in Metal

When you use threaded inserts in metal components, there are advantages to enjoy! These little items boost the connection’s durability and strength by spreading the stress across the material, which helps prevent stripping and wear over time, especially in those softer metals! On top of that perk, they also make it easy to take things apart and put them together without messing up the threads. Perfect for situations where you need to maintain or swap out parts often!

Preparing for Installation

A key factor in ensuring the installation of threaded inserts into metal surfaces is thorough preparation, which includes choosing the appropriate insert type and gathering all required tools.

Selecting the Appropriate Insert Type

Selecting the type of insert is influenced by various factors such as the host metal’s material composition and strength needs, and the surrounding environment’s conditions to consider when choosing the best option for a specific application scenario. For example, helical inserts are ideal for lighter-duty tasks that require vibration resistance; in contrast, solid inserts are recommended for applications demanding strength levels.

Tools Required for Installation

For an installation of threaded inserts, you will require certain tools including a drill bit that fits the size of the insert, a tap to form threads in the hole (if not using self-tapping inserts), an installation tool or driver suitable for the type of insert, and a torque wrench to ensure proper tightening without damaging the material excessively.

Techniques for Installing Threaded Inserts

The setup procedure requires methods to guarantee the proper positioning of the insert in the metal base.

Drilling and Tapping the Hole

The initial stage involves drilling a hole that aligns with the requirements specified for the selected insert accurately and meticulously to prevent any misalignment or compromise in the integrity of the material. In cases where self-tapping inserts are utilized, tapping becomes essential to establish internal threads that correspond to those of the insert.

Inserting the Threaded Insert

Once the hole is ready to go and all set up nicely for you to work with it smoothly, it’s time to carefully insert the threaded insert into place using the tool for the job that matches its style and design specifications. Make sure to drive or screw it in carefully until it sits nice and flush with the material’s surface or a tad below for that perfectly seamless look and to avoid any clashes with other parts around it.

If you’re in the market for notch-threaded inserts and associated fasteners, QEWIT is a standout choice for reliable supply needs. QEWIT is dedicated to delivering high-quality products and prides itself on offering exceptional customer services and technical assistance to ensure customer satisfaction. Their product selection encompasses a variety of fasteners crafted from materials such as brass and stainless steel—all supported by stringent quality assurance protocols.

Implementing these methods in your projects guarantees that your setups are strong and dependable for long-term use in any situation that demands secure fasteners for metal surfaces.

Ensuring Optimal Performance

Testing the Installed Insert

Once you’ve installed the threaded inserts in place as needed, it’s important to check how well they work to make sure they meet the standards. To do this test properly, make sure the insert is in place and aligned correctly within the metal base. Apply the recommended amount of force to the fastener, ensuring it can handle the pressure without getting damaged or coming loose. This step confirms that the installation went well and that the insert can be trusted to work when needed.

Troubleshooting Common Issues

With a precise setup process in place for threaded inserts, installation can still lead to some challenges cropping up at times. The common issues that might surface include misalignment problems where the insert doesn’t align correctly or provide a grip or even thread stripping concerns. To address these hitches effectively, it’s crucial to examine the installation location for any signs of damage or debris that could impact its functionality. In case of misalignment occurring, it’s wise to think about re-drilling and tapping the hole anew. To tackle grip problems, ensure that you’ve used the right type of insert suitable for the material and load demands. If you notice signs of thread stripping, evaluate if excess torque was applied during the setup process and make necessary adjustments accordingly.

Advanced Tips for Professionals

Custom Solutions for Unique Applications

In situations where professionals come across special uses that demand customized solutions exceeding regular threaded inserts, it’s worth looking into personalized products crafted to meet precise requirements such as unconventional sizes or materials suited for specific environmental challenges or pressures. Teaming up with a supplier to create tailored inserts could greatly improve the effectiveness and durability of the application.

Maintaining Threaded Inserts in High-Stress Environments

In high-pressure settings like those where threaded inserts are commonly used in machinery and structures that undergo stress levels over time, require regular upkeep to uphold their effectiveness and durability. Make it a habit to check the condition of these threaded inserts at intervals to detect any signs of deterioration or rust buildup, paying particular attention in environments with harsh elements like exposure to chemicals or moisture. If needed, apply protective coatings on the inserts as a preventive measure against wear and tear caused by external factors and promptly replace any inserts that show signs of damage to prevent potential breakdowns or malfunctions.

Integrating QEWIT Products with Threaded Inserts

Overview of QEWIT’s Offerings

Since 2004 QEWIT has been providing a selection of fasteners and fixings for different industrial uses globally and in Europe too! Known for their top-notch products and strict quality standards, they offer threaded inserts crafted from materials, such as brass, stainless steel, aluminum and alloys.

Recommendations for Specific Applications

If you’re looking for corrosion resistance or strong tensile strength in your applications, you should think about using QEWIT’s stainless steel threaded inserts. These are perfect for places that deal with moisture or chemicals because of their build and resistance capabilities. For light-duty uses where vibration resistance is important, consider choosing helical inserts from QEWIT’s selection.

For information on the wide range of products they offer and to discover solutions customized to your unique requirements, check out QEWIT. With a dedication to ensuring customer happiness through exceptional service and tech assistance, QEWIT delivers practical solutions that effectively cater to various industrial needs.

By following these recommendations and incorporating top-notch products such as those provided by QEWIT into your assignments, you can set up threaded inserts on different types of metal surfaces.