caTEGORIES

Tags

How to Ensure Perfect Fit with Self-Tap Screws Every Time

Posted: February 13, 2025

Categories: News

How to Ensure Perfect Fit with Self–Tap Screws Every Time

Self-tap screws are made to create threads when driven into a material and are achieved by a multitude of uses. Choose the self-tap screw according to the thickness and density of the material. Even if self-tap screws can be inserted directly into the materials, it is important to consider whether the material should be created and use the drilling method when necessary.

The Mechanics of Self-Tap Screws

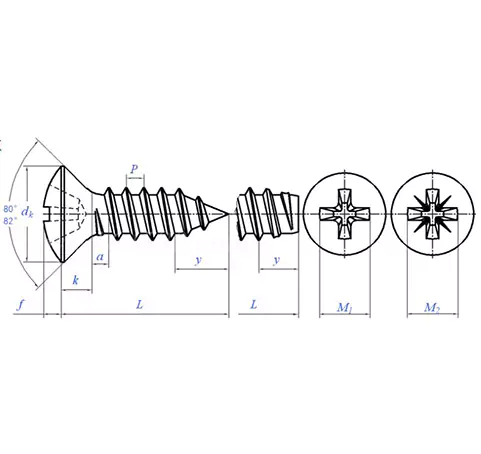

The Design and Functionality of Self-Tap Screws

A great engineering innovation is seen in the design of self-tap screws, which form their threads during installation into the material—a crucial characteristic in situations where pre-tapped holes cannot be used in various applications. They come in cutting-edge screws that are capable of penetrating the metal, polymers, and wood and become the ensuring body to create secure and sturdy assemblies.

Types of Self-Tap Screws for Different Applications

Choosing the Right Self-Tap Screw for Your Material

Choosing the self-tap screw is important as it determines the efficiency of the project for which you use it! While using certain materials like plastic, choosing screws is advisable if the screw has a thread guarantee grips without damaging the material itself. If you are using something like metal for your project purposes, you should have more sophisticated threads so there is no danger of breaking or splitting.

Comparing Self Tap Screws with Traditional Screws

The biggest advantage self-tap screws have over conventional screws is that they can be driven directly into materials without a pilot hole. This leads to bypassing the demand for additional tools and equipment, thus saving time. A self-tap will go in like butter, just have to be careful that the integrity of the material doesn’t get compromised.

Preparing Materials for Optimal Performance

Assessing Material Compatibility with Self-Tap Screws

The use of self-tap screws, however, requires an assessment as to whether the material is compatible with self-tap screws. Other materials are either too delicate or too malleable to support the screw threading. This can help you determine whether the material is strong enough to withstand the pressure in the test or if it will break.

Pre-drilling Techniques for Different Materials

Determining the Appropriate Drill Bit Size

There are times when pre-drilling is required for proper installation to prevent damage to the material you are working with. It’s important to use a drill bit of the correct size, which should be a little bit smaller than that of the screw so that you can thread it smoothly without applying too high pressure.

Ensuring Clean and Precise Pre-drilled Holes

The key to drill smooth, pre-drilled holes would be to maintain a consistent pressure and speed throughout the drill to ensure there are no burrs or imperfections that would prevent the screw from functioning correctly. Getting the drill aligned means that the screw will go in straight and bite exactly as it ought to. Your drill is aligned to make sure you get that screw in as straight and stable as desired.

Techniques for Driving Self-Tap Screws Efficiently

Selecting the Right Tools for Installation

Manual vs. Power Tools: Pros and Cons

The difference between tools and power tools depends on what you specifically need. When using fragile materials, speed and pressure are an important factor—something manual tools have an advantage in. Power tools are much more efficient, but they must be handled with care to avoid overtightening or stripping them.

Step-by-Step Guide to Driving Self Tap Screws

Aligning the Screw Correctly

Cross-threading or misalignment could result in a joint that does not hold. Now, be careful to angle the screw at an angle to the surface before applying any pressure. Be careful to angle the screw to the surface before applying any pressure.

Applying Consistent Pressure and Speed

With these self-tap screws, you want to maintain the pace and pressure so that you do not cause any damage while allowing the screw to insert easily into the material. When using self-tap screws, it is necessary to keep the pace and pressure, not to damage, but to screw them into the material you are working on.

However, if you are on the lookout for the best of the best fasteners that suit your needs, maybe check out QEWIT. They are one of the trusted fasteners manufacturers who truly specialize in designing quality fasteners for sectors. Not only does QEWIT provide top-notch customer support, but they also provide customized product options based on your requirements. And, they have got support to be able to give you peace of mind while you benefit from market-leading products, such as their self-tap screws readily available for different international applications!

Avoiding Common Pitfalls During Installation

Identifying Signs of Over-tightening and Stripping

During installation, if you start tightening self-tap screws, it will strip the threads and further lose the strength of the material. The solution here is to remember some warning signs that you can look for, such as the tightening feeling becoming laborious or the sudden release of resistance. If the screw simply spins in place, it means the threads are stripping and you need to immediately address the situation to maintain the structural integrity of the part of the profile holder.

Best Practices to Prevent Material Damage

Adjusting Torque Settings Appropriately

While fastening using self-tap screws is performed fairly easily, because of the nature of how they work, you need to be careful not to over-torque. It is important to adjust the settings on your tool so that you do not apply more force than necessary during the whole fastening process—just enough to secure the screw but not so much that the material bends and breaks.

Using Lubricants for Smooth Insertion

Lubricants reduce friction during driving and heat build-up that could damage threads on screws or break screws themselves, which can make easier insertion of true self-tap screws (if desired). Use a lubricant that is compatible with not only the screw but also with the material to avoid any reactions. Very important to use a lubricant that is compatible with both screw and material to avoid any reaction.

Maintenance and Inspection After Installation

Regular Checks to Ensure Secure Fittings

Periodical inspection contributes to maintaining the quality of works built up with self-tap screws. Watch for signs of looseness and rust that can put the durability of the connection at risk. Addressing such issues promptly prevents breakdowns and helps increase the life of your setups. Timely solutions to these issues can help avoid breakdowns and maximize the life of your equipment.

Troubleshooting Loose or Damaged Screws

If you encounter your project or item with stripped screws, check to see if retorquing them will fix the problem or if refitting with new screws is required. If you tried to reinforce the joint with something like washers, replace the screws with similar screws that came with it to avoid any more complications.

Recommendations for Using QEWIT Products with Self-Tap Screws

Advantages of QEWIT Products in Enhancing Screw Performance

QEWIT offers a range of fastening products that are engineered to perform best in all usages. Their products are known for their quality and reliability—ideal for efforts that require precision and durability. With QEWIT offerings you have the peace of mind that comes from customer service, coupled with expert technical assistance & tailored solutions that meet your individual needs.

Tips on Integrating QEWIT Solutions into Your Projects

With QEWIT products in your projects, it will not only be the variety of products that you can utilize in your projects but also the technical involvement that you will get in your projects and implementations. Selecting fasteners like threaded inserts & self-tap screws (among other options) that meet the exact needs of your material and the details of your project will deliver the best results. Hop in QEWIT for full product specification and doing a tailored job enhancing your project performance.

Using notch fastening materials such as that of QEWIT whilst following these recommendations gives your constructions solid lasting and reliable structures to accommodate the various operational requirements. As long as these tips are followed, together with notch fastening materials such as those the QEWIT offers, you can rest assured your builds will be strong and reliable enough to serve different operational requirements well.