caTEGORIES

Tags

Avoid Costly Fastener Failures: The Engineer’s Checklist for Perfect Rod And Stud Sizing

Posted: March 27, 2025

Categories: News

The engineer wants to avoid the expense of a fastener failure, so he follows a checklist for sizing rods and studs to a tee. It is about having the right nuts and bolts for the connection to hold and be able to have it re-tightened without any issue. It is essential to measure based on these procedures, as dimensions that are not accurate can lead to weak and unsafe connections.

The Importance of Correct Rod and Stud Sizing

The Role of Rods and Studs in Engineering Applications

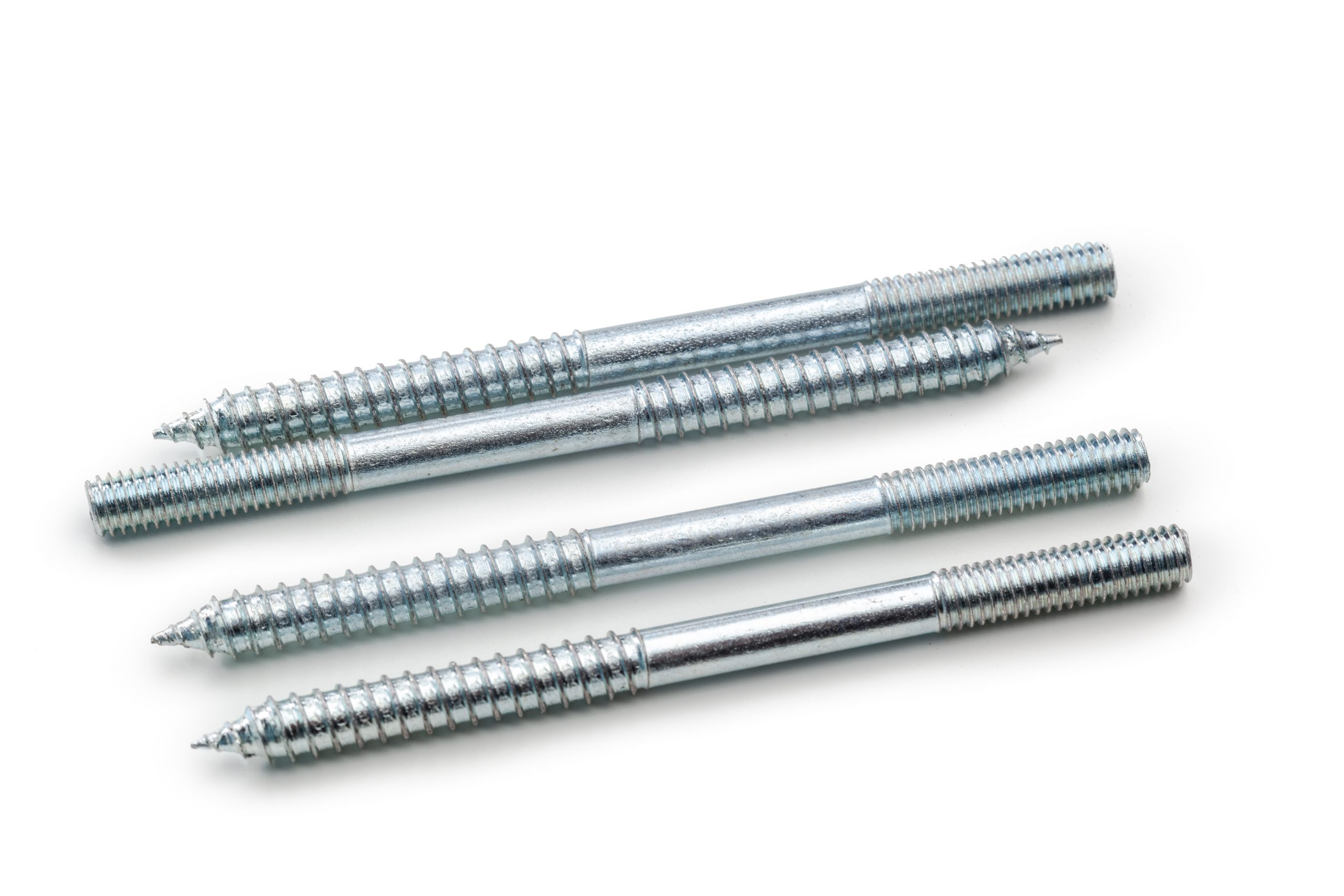

Rods and studs are used in many engineering applications. They act as primary fasteners that are used to hold structures together stably and reliably. These parts are commonly used in sectors such as welding and automotive industries where precision and strength are essential. Choosing the correct size for rods and studs is necessary to hold the entire assembly. This decision affects the performance and safety of engineering projects.

Consequences of Incorrect Sizing

If rods and studs are off even a little, there could be catastrophic results. If these systems are not properly sized, then they can fail in load resulting in structural or machinery catastrophic failures. These types of failures can lead to expensive repairs, unscheduled service, or even safety hazards. This is why it is so important to size rods and studs accordingly to avoid these possible problems.

Industry Standards and Guidelines for Sizing

There are guidelines for standard rod and stud sizing that will ensure that they perform great for you. They include material specifications, dimensional tolerances, and mechanical properties, among other things. Following these principles assists engineers in determining the proper size of a given application, guaranteeing the desired component is compatible with others and meets safety regulations.

Determining the Appropriate Size for Rods and Studs

Factors Influencing Size Selection

Rods and studs differ heavily in their method of sizing based on the load requirements of an application. Evaluate the static and dynamic loads that the fasteners will work with during the service life. This is critical to ensure the selected size will withstand these loads without deformation or failure, which affects structural safety.

One of the important factors that also decide the proper size of rods and studs is environmental conditions. Changes in material properties of the fastener due to temperature variations, exposure to corrosive elements, high humidity, etc. Choosing a size that can tackle these environmental challenges will help ensure durability and performance.

Another important consideration in the choice of rod and stud sizes is material compatibility. The selected material should also be compatible with other elements in your system, related both to mechanical properties and chemical resistance. It avoids galvanic corrosion or other adverse interactions between dissimilar materials.

Calculating the Correct Diameter and Length

Computing the proper diameter and length must take into account the mechanical and practical characteristics of your application. Optimum dimensions must be determined using engineering equations that add a few more variables including tensile strength, shear strength, and elongation limits.

Selecting the Right Thread Type for Your Application

Different Types of Threads Available

There are different types of threads used on rods and studs, each suitable for specific applications. Some of the common thread types are coarse threads, fine threads, metric threads and unified threads. In terms of load-bearing, ease of mounting, or lack of looseness under vibration, one type is better than the other. Each type gives you any number of advantages in one area or another.

Considerations for Choosing Thread Type

Several factors may impact the type of threads you use in your application, whether it be easy assembly needs or exposure to potentially vibrational forces that require locking features such as nylon inserts or serrated flanges. Also assess the need for self-locking based on the operational conditions.

Tools and Techniques for Accurate Measurement and Installation

Essential Measuring Instruments for Engineers

Measurement is extremely important for the right sizing of rods and studs. Engineers need to use a variety of measurement tools to guarantee accuracy. Examples of such tools include calipers, micrometers, and thread gauges; these provide an immediate reading of precise measurements for diameter, length, and thread pitch. These tools must be used to ensure that the parts conform to design specifications & industry standards.

Techniques to Ensure Precision in Measurement

Measurement has a few more techniques that are very precise. For this reason, engineers are expected to regularly calibrate their instruments. You should measure at some points down the rod or stud due to manufacturing inconsistencies. Also, there are some environmental factors, for example, the temperature, that affect the measurements.

Installation Best Practices to Prevent Failures

Rods and studs can fail if installed incorrectly, so proper installation practices are critical. The threads must be free of debris before assembling. We need to use the appropriate torque levels on fitments, otherwise many fasteners will get overstressed. To further increase the security of the assembly, thread-locking compounds or self-locking nuts can be used.

Common Challenges in Rod and Stud Sizing and How to Overcome Them

Identifying Potential Pitfalls in Sizing

A frequent problem concerns finding a size with sufficient mechanical property, yet small enough to fit in an assembly somewhere. If not accounted for properly, these can lead to poor load-bearing or may clash with other components. Not taking the long-term effects on the material properties of the environment into account is another pitfall, as this may put the performance out of function after a time.

Solutions to Address Common Issues

Engineers should do a load analysis and environmental assessment for potential issues in the design phase. Simulation software can be used to predict performance in different conditions. Resourceful suppliers can be another source of technical support and can assist in determining appropriate materials and sizes for the application.

QEWIT’s Solutions for Optimal Rod and Stud Performance

Overview of QEWIT’s Product Range

QEWIT is a one-stop shop for any kind of fasteners for any application. From threaded inserts, bolts, screws, nuts and washers, to threaded rods & studs, they provide engineering products. They also offer non-standard products with tailored solutions available on request.

How QEWIT Products Ensure Reliability and Efficiency

This commitment to quality assurance ensures that all products meet high standards. And they ensure that products are always good quality. The fasteners they produce are provided with test certificates for mechanical properties such as tensile strength and corrosion resistance. It is then bolstered by their ISO 9001 certification process.

If someone wants performance features like corrosion resistance or vibration resistance, they have the options of “Nylon Insert Nuts DIN 985” or “Hexagon Serrated Flange Nuts DIN 6923” to address these common operational problems. Nylon Insert Nuts or Serrated Flange Nuts, for example, fill a niche by providing corrosion or vibration resistance, respectively, for any performance features you may require.

FAQs

Q1: What tools are essential for measuring rods and studs accurately?

A: Calipers, micrometers, and thread gauges are essential tools for precise measurement of dimensions like diameter, length, and thread pitch.

Q2: What are some best practices during installation to prevent failures?

A: Ensure threads are clean before assembly; use appropriate torque levels; apply thread-locking compounds or self-locking nuts for enhanced stability.

Q3: How does QEWIT ensure the reliability of its fasteners?

A: They provide test certificates verifying mechanical properties; their products comply with ISO 9001 standards ensuring consistent high quality.