caTEGORIES

Tags

What is the Superiority of Machine Screws over Other Screw Types?

Posted: November 26, 2024

Categories: News

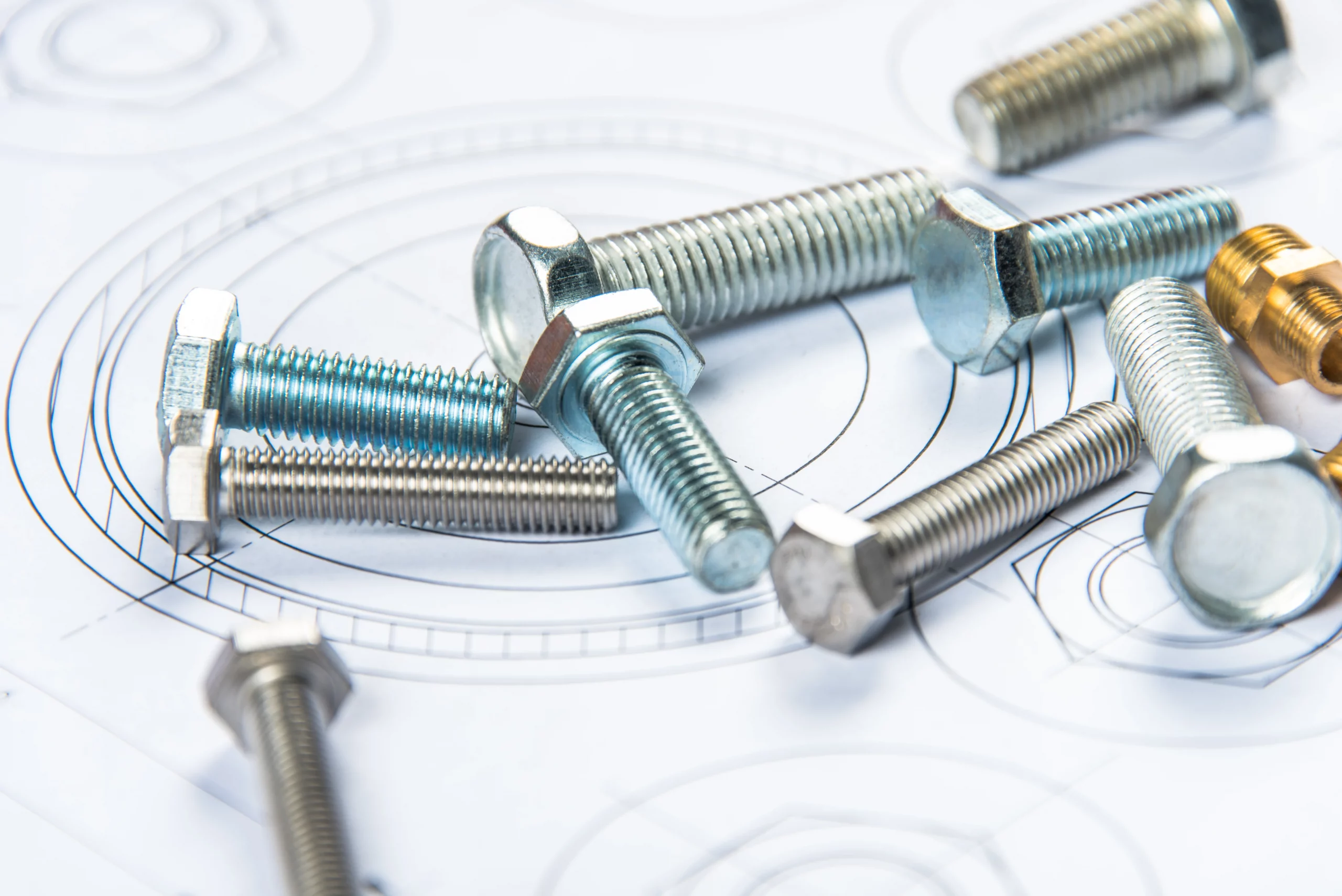

Machine screws offer versatility, strength, corrosion resistance, and refastening capability, making them a superior choice compared to other screw types for various applications. This blog will show you the superiority of machine screws.

What Are Machine Screws?

Machine screws are screws with threads that are used to fasten two objects securely and are equipped with a distinctive head for easy handling using a screwdriver tool.

You can fasten machine screws into threaded or drilled openings for a snug fit without requiring a nut to secure the screw in place.

Machine screws are designed with threading throughout their length to offer a larger surface area for securely fastening metal parts together.

Types of Machine Screws

There are many types of machine screws. This part will introduce five types.

Phillips Head Machine Screws

Phillips head machine screws feature a shaped recess at the top that accommodates a Phillips screwdriver for precise control and minimized slippage compared to flat head screws. They are widely employed in electronic assembly processes as in the manufacturing of household appliances and industrial equipment.

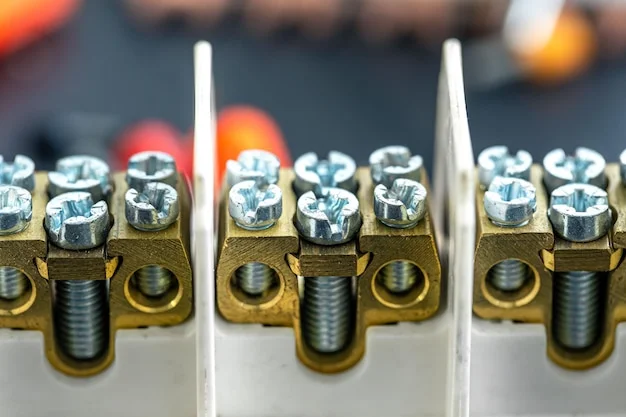

Slotted Head Machine Screws

Slotted head machine screws have the horizontal slot running across the head and need a flat head screwdriver for installation purposes. Although they may not provide the precision as Phillips head screws do their design and timeless appearance distinguish them. You can commonly spot these screws in outlets, fixtures, and when assembling furniture.

Hex Head Machine Screws

Hexagonal machine screws feature a six-head that requires the use of a wrench or socket tool for installation purposes. The unique design enables them to handle torque levels effectively making them ideal for heavy-duty tasks. They are commonly used in machinery, engines, and construction equipment.

Torx Head Machine Screws

Star head machine screws known as Torx screws feature a recess with a six-pointed star shape that enhances torque transfer during assembly and reduces the likelihood of slip-outs when high torque is applied by the screwdriver blade. These screws are frequently used in electronics as in agricultural machinery and construction and industrial equipment.

Combination Head Machine Screws

Multi-purpose machine screws with drive options like Phillips and slotted or Phillips and hex are practical as they can be manipulated using tools for better compatibility and ease of use across a range of applications in consumer electronics and building sectors including HVAC systems.

Common Machine Screw Sizes and Applications

Different sizes of machine screws can be found based on their length and diameter as the thread pitch they have available for use. The length is measured from the bottom of the head to the tip while the diameter is specified in inches for screws and millimeters (mm). This measurement indicates the thickness of the screw shank.

The thread pitch is the spacing between threads on a screw or bolt shaft. A finer thread pitch means there are threads per millimeter or inch. This results in a connection that can withstand vibrations better but requires force to tighten securely. Conversely, a coarser thread pitch allows for fastening. May provide less gripping strength.

The primary criteria for determining the dimensions of machine screws are established by the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI). In ISO specifications for screws, sizes are denoted by an M followed by a diameter in millimeters like M6 while ANSI screw sizes feature a symbol along with a number representing the diameter and thread count per inch separated by a dash such as 11 31.

Advantages of Machine Screws

Advantages of machine screws in many applications determines its superiority.

Versatility

A wide range of machine screws can be found in sizes and materials with head styles to meet the specific requirements of various applications. They are commonly used as fasteners to connect surfaces and objects in a variety of industries.

Strength

Machine screws offer a durable hold when fastening parts together securely with their threading and strong materials that ensure a snug fit perfect for tough tasks like heavy-duty applications The durability of these screws ensures components stay firmly attached even in challenging conditions such as stress or vibration.

Corrosion Resistance

Machine screws made of steel or aluminum with plating provide protection against corrosion—a key factor for situations where exposure to chemicals or severe weather is a concern.

Refastening Capability

Having the tools at your disposal allows you to remove and reuse machine screws effectively without causing any harm to the parts they secure in place. This ability to fasten and refasten is particularly useful in tasks involving maintenance and repairs that require assembly and disassembly of components.

Qewit: A Reliable Machine Screws Supplier

The company QEWIT FASTENERS CO., LTD., a British-owned enterprise located in Qingdao in the Shandong Province of China is dedicated to providing a selection of “Industrial Consumable Products” to customers across Europe and globally.

Established in 2004 Qewit follows the guidance of its owners shaping its approach to managing the supply chain for consumables sourced from mainland China and neighboring regions such as Taiwan, Malaysia, Vietnam, and Thailand.

Product Range

At Qewit offerings include fasteners in grades such as grade and high grade as well as fasteners crafted from Brass/Copper materials and Stainless Steel along with aluminum and alloy options available with test certificates ensuring professional quality control and traceability.

Qewit has the setup and expertise to provide you with a cost service that meets your needs such as personalized “Account Management” “Quality Assurance” tailor-made specialty items ” and secure “Packaging & Shipping.”

Quality Assurance

At Qewit they make sure that their products maintain a level of quality at all times. They and the suppliers they work with are both certified with ISO 9001. Every factory has inspections and audits with quality control plans and testing programs implemented.

We can provide a 3 Point One certification for fasteners as an added service if needed; we also offer advanced certifications like ISIR (Initial Sample Inspection Reports ) and PPAP (Production Part Approval Process).

Service and Support

At Qewit we take pride in our customer service offerings which encompass a variety of services such as;

-

- Consolidation Service:Qewit offers a free consolidation service. No matter how diverse your ordered products are, they are able to collect all of them to their one hub before they are loaded and sent to the yard.

- Technical Support:Qewit offers technical support to customers. With their testing facilities, they can proceed with outgoing inspection processes, ensuring products conform to the relevant international standards. When customers have concerns about quality, they can respond quickly by giving the filed sample batch a re-test. Customers can rest assured when reports or test videos are received.