caTEGORIES

Tags

When to Use Coach Bolts: Understanding Specific Applications

Posted: October 15, 2024

Categories: News

Lag bolts, also known as coach bolts, are essential fasteners used in construction projects involving timber and metal structures. These bolts are highly valued for their durability and strength characteristics. They are designed with a head and square neck, which prevents them from rotating during installation. This unique feature allows for secure attachment and increased load-carrying capacity. In industries such as construction and engineering, understanding the applications of coach bolts is crucial for maintaining the stability of structures and achieving project objectives.

Qewit Fasteners is a reputable provider in the fastening industry, offering a wide range of high-quality products, including customized coach bolts. They prioritize the highest quality standards and customer satisfaction by ensuring that each product is durable and reliable. Qewit Fasteners is dedicated to meeting the needs of professionals seeking reliable fastening solutions. Their product design philosophy revolves around providing top-notch products and leveraging the expertise and assistance of industry professionals. By choosing Qewit Fasteners, customers not only gain access to premium fasteners but also benefit from the wealth of knowledge and support offered by industry experts.

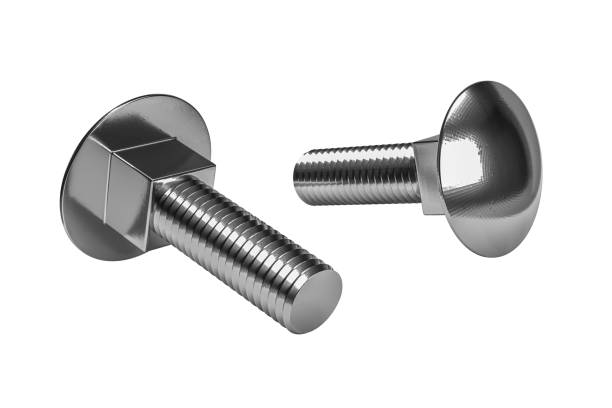

Definition and Characteristics

Coach bolts are known for their design featuring a round top and a screw-like threaded shaft made of sturdy materials like steel to handle heavy loads and resist shear and pull-out forces effectively. Their square neck offers a turn feature for easy tightening using a wrench without extra support required. This makes coach bolts a great option for projects needing a reliable fastening solution, in situations where high strength is crucial.

Importance in Construction and Engineering

Coach bolts are important components used in the construction and engineering industries to connect different structures such as timber frames and metal joints. They are also commonly used in outdoor furniture projects. The main purpose of coach bolts is to create strong connections, ensuring the stability and durability of constructions. By selecting coach bolts, professionals can have confidence in the long-term integrity of their projects, without the need for frequent maintenance or repairs. The careful choice of fasteners, including coach bolts, is crucial as it guarantees that the structural elements will remain securely intact throughout their lifespan.

Specific Applications of Coach Bolts

Timber Construction

Benefits of Timber Structure

Coach bolts are highly favored in construction projects due to their excellent grip and user-friendly characteristics. They are widely used by both builders and carpenters. The substantial diameter and robust threads of coach bolts enable them to firmly anchor into the wood, creating a strong and long-lasting connection between timber pieces. This is especially important when working with beams that undergo both tension and compression forces during the construction process. Utilizing coach bolts, ensures that the connections remain secure and stable, providing a solid foundation for the entire structure.

Usage Examples in Timber Frames

Coach bolts are frequently used in timber framing, for purposes such as building houses and outdoor structures like decks and pergolas well as furniture assembly tasks. For example in the construction of decks or pergolas coach bolts play a role in attaching the frame securely to support posts or beams. They are also commonly employed in putting together timber trusses that require load-bearing capabilities. Using coach bolts, in these scenarios helps improve the stability and safety of timber structures.

Metal Fabrication

Advantages in Metal Works

Coach bolts are highly advantageous when it comes to metal fabrication workstations and tools. These robust fasteners are specifically designed to create strong connections between metal parts, even in challenging conditions with heavy strains. Their ability to withstand heavy loads without failing makes them an ideal choice for various applications, including manufacturing machinery and constructing structures. Additionally, coach bolts can be plated or coated to protect against rust and corrosion, ensuring their longevity and optimal performance in different environments.

Common Uses in Metal Joints

Typical applications of coach bolts, in metal connections involve putting together steel frameworks in constructions and industrial facilities for added strength and stability in systems like girders and columns, under varying loads to enhance the durability and efficiency of construction projects overall.

Outdoor Furniture and Structures

Durability in Outdoor Conditions

Outdoor furniture and structures rely heavily on the durability of materials used in their construction process. The superior strength and resilience, to influences make coach bolts an excellent choice for applications. These sturdy fasteners are specifically crafted to withstand weather conditions such as rain and humidity that may lead to the degradation of fastening solutions. Opting for coach bolts will help maintain the appeal and safety of your structures, in the long run.

Back of the wooden bench.

Application in Garden Sheds and Benches

Coach screws are commonly used in the construction of garden structures and seating areas where durability and stability are important factors. In the context of garden structures such as sheds or benches, coach screws are used to secure the framework and roof components, allowing the building to withstand weather conditions and external pressures. For seating installations like benches, coach screws are essential for connecting the seat with its legs and support bars, ensuring that they can effectively bear weight without compromising functionality. The use of coach screws in these scenarios not only extends durability but also enhances the visual appeal of outdoor furnishings and constructions.

In summary, coach bolts are highly valued for their effectiveness in securing materials like wood and metal in various industries. Their strong construction and user-friendly features make them a crucial choice for professionals who prioritize the stability of their constructions. If you are looking for high-quality coach bolts and professional advice, consider partnering with Qewit Fasteners. They specialize in offering products that meet the requirements of your projects, ensuring that your constructions remain sturdy and long-lasting.

Factors to Consider When Choosing Coach Bolts

Material Selection for Coach Bolts

Selecting the material, for coach bolts is essential to ensure top-notch performance in your projects, Stainless steel and carbon steel with coatings are commonly utilized in the production of coach bolts.

Stainless Steel vs. Galvanized Coatings

Stainless steel coach bolts are highly valued for their ability to resist corrosion efficiently and are perfect, for use in environments that face moisture or harsh conditions head-on. On the other hand galvanized coach bolts come with a zinc coating that acts as a shield against rust and prolongs their lifespan when utilized outdoors or in surroundings. Even though galvanized alternatives may be cheaper stainless steel is typically the choice for scenarios requiring exposure, to varying weather conditions.

Impact on Longevity and Corrosion Resistance

The choice of the material significantly influences how durable and effective coach bolts are, in situations like humidity or exposure to chemical environments where stainless steel bolts tend to outlast galvanized ones Select the right material, for your project by considering these distinctions and the environmental conditions involved.

Size and Length Specifications

When thinking about using coach bolts for your project needs it’s important to grasp the size and length requirements to ensure they’re a fit, for what you’re working on.

Matching Bolts with Project Requirements

Coach bolts are available, in a range of sizes and lengths to meet construction requirements It’s important to choose the right bolt size based on the material thickness and the type of joint being secured Using the size of a coach bolt helps ensure a secure connection and lowers the risk of material failure Take precise measurements of your project components to determine the suitable bolt size that can provide the required strength and stability.

Load-Bearing Considerations

When choosing coach bolts, for your project’s needs it’s essential to consider the amount of weight they will bear during use. The ability of a coach bolt to bear weight is influenced by its size, length, and the material it is anchored in. It is important to refer to load guidelines and engineering standards to verify that the coach bolts you choose can handle the anticipated loads and forces over time in your construction work.

Comparing Coach Bolts with Other Fasteners

When looking at fastening solutions, analyzing the differences among various fasteners can inform your choice of coach bolts about their competition.

Differences Between Coach Bolts and Carriage Bolts

While both coach and carriage bolts are utilized for securing timber and metal structures, they exhibit distinct differences in design and application.

Carriage bolts feature a round head and a smooth shaft, which requires a nut on the opposite side to create tension. They do not possess an anti-rotation feature, which can lead to complications during installation. With their square neck and unique head design, Coach bolts remain fixed during tightening, providing more reliable fastening with consistent pressure. This inherent grip enables them to perform well in heavy-duty applications, solidifying their position in construction and engineering projects.

Situations Where Coach Bolts Are Preferable

Certain scenarios dictate the use of coach bolts over other fasteners for optimal performance. Coaching bolts are preferred due to their superior strength and resistance to shear loads when high load-bearing capacities are necessary, such as in structural framing and heavy-duty machinery.

Furthermore, coach bolts are advantageous in situations where ease of installation is key. Their design allows for quick tightening with a wrench, eliminating the need for additional tools to prevent rotation, as with other types of fasteners. These factors make coach bolts a go-to choice for professionals in challenging environments, ultimately enhancing the efficiency and reliability of assemblies in various settings.

In summary, careful consideration around material selection, sizing, and the specific advantages of coach bolts compared to other fasteners plays a crucial role in ensuring the success of your projects. With the expert offerings of Qewit Fasteners, you can access a wide range of high-quality coach bolts designed to exceed your expectations in every application. Whether you’re focusing on timber framing or metal fabrication, Qewit has the reliable fastening solutions your projects require. Prioritizing these factors will lead to greater structural integrity and longevity in your work.