caTEGORIES

Tags

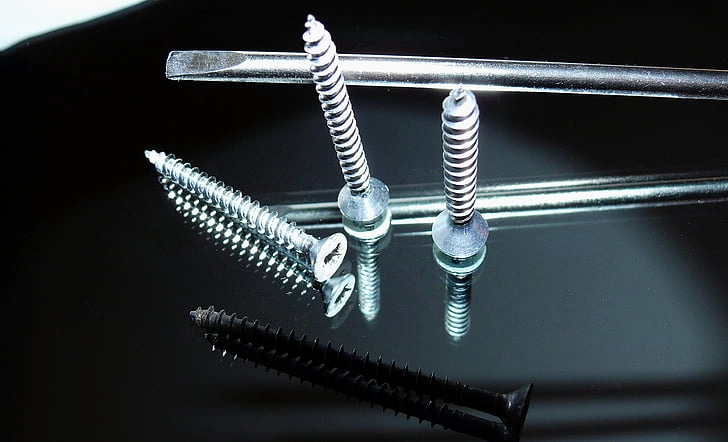

Coarse-Thread vs. Fine-Thread Drywall Screws A Comprehensive Guide

Posted: July 23, 2024

Categories: News

Tags: news

Understanding Drywall Screws

What Are Drywall Screws?

Drywall screws are specialized fasteners used to secure drywall to either wood or metal studs. These screws are engineered to ensure a firm grip and easy penetration into the material. In contrast to regular screws, drywall screws feature a bugle-shaped head and a deeper thread design, which helps prevent the material from cracking while ensuring a snug fit. Made from hardened steel, drywall screws are available in two types: coarse-thread and fine-thread, each suited for different installation needs.

Historical Context and Evolution of Drywall Screws

Historically, nails were primarily used for securing drywall sheets. However, nails often resulted in minor damages and a lack of secure fastening, leading to innovations over time. The introduction of drywall screws marked a significant leap forward in drywall installation. Their design allowed for better grip, ease of use, and a more secure fastening. Over the decades, the manufacturing and quality of drywall screws have improved significantly, thanks to advances in technology and materials. Today, drywall screws are indispensable in construction and renovation projects.

Qewitco has persistently focused on producing and trading high-quality, reliable products. The company’s operational principles, which are deeply influenced by its former British owners and directors, have been crucial in managing the supply chain of industrial consumable goods from mainland China and neighboring countries such as Taiwan, Malaysia, Vietnam, and Thailand. This combination of Western business expertise and Far Eastern values enables Qewitco to provide outstanding products and services to its international customers.

Coarse-Thread Drywall Screws

Characteristics of Coarse-Thread Drywall Screws

Coarse-thread drywall screws have widely spaced threads, which make them ideal for working with softer materials like wood. These screws dig into the wood without requiring excessive force, providing a robust and durable hold. Typically, coarse-thread screws are also treated for better corrosion resistance, increasing their longevity. They usually have a sharp point, allowing for easier penetration without pre-drilling.

Advantages of Coarse-Thread Drywall Screws

One of the primary advantages of coarse-thread drywall screws is their strong holding power when used in wood. The larger thread design allows for greater grip and less chance of stripping the hole. This means that the connection stays secure over time, even as the wood expands or contracts with changes in humidity. Additionally, the wide thread design makes installation faster since fewer turns are needed to sink the screw into the material.

Best Situations to Use Coarse-Thread Drywall Screws

Coarse-thread drywall screws are best suited for attaching drywall to wooden studs and frames. They are ideal in residential construction where wooden framing is common. Additionally, they are effective for projects requiring thick layers of drywall or where multiple sheets are to be joined. They also perform well in outdoor projects, provided they have the necessary corrosion-resistant coating. Lastly, these screws are favorable in settings where installation speed is crucial due to their ability to penetrate materials quickly.

Fine-Thread Drywall Screws

Characteristics of Fine-Thread Drywall Screws

Fine-thread drywall screws feature more closely spaced threads compared to their coarse-thread counterparts. This design allows for finer adjustments and a more precise fit. These screws are typically made from hardened steel and often come with a self-tapping point, making them suitable for metal applications. The narrow threads provide a cleaner penetration into the material, reducing the risk of damage or splits in finer or more brittle materials. Fine-thread screws usually have a phosphate coating to prevent corrosion over time.

Advantages of Fine-Thread Drywall Screws

One of the main benefits of fine-thread drywall screws is their compatibility with metal studs. The fine threads allow for a secure grip within metal framing, which is critical for maintaining structural stability. Additionally, fine-thread screws are less likely to bulge the surface of the drywall, providing a smoother finish. This makes them preferable in interior applications where aesthetics are important. Their finer threads also mean they accumulate less debris, maintaining their performance over longer periods.

Ideal Scenarios for Using Fine-Thread Drywall Screws

Fine-thread drywall screws are ideally suited for attaching drywall to metal studs. They are commonly used in commercial construction projects where metal framing is more prevalent. These screws are also a good choice for installing thinner drywall sheets or when working on ceilings, as the fine threads provide a secure hold without damaging the surface. Additionally, they are useful in environments where a smooth finish is paramount, such as in finishing walls that will be painted or wallpapered.

Comparing Coarse-Thread and Fine-Thread Drywall Screws

Differences in Design and Structure

The primary difference between coarse-thread and fine-thread drywall screws lies in their thread spacing. Coarse-thread screws have wider, more pronounced threads, while fine-thread screws feature narrower, closely spaced threads. This design distinction impacts their performance and suitability for various materials. Coarse-thread screws penetrate softer materials effortlessly and provide robust holding power, whereas fine-thread screws excel in providing a secure fit within metal. Both types are typically designed with a bugle head to prevent damage to the drywall surface during installation.

Performance Comparisons in Various Applications

Strength and Holding Power

In terms of strength and holding power, coarse-thread drywall screws are generally superior for wood applications. The wider threads enable a stronger grip in wood, which is crucial for ensuring long-term structural integrity. Fine-thread screws, while offering adequate holding power in metal, may not provide the same level of security in wooden installations. However, fine-thread screws are more effective in maintaining their grip in metal due to their design, which is optimized for metal penetration and a snug fit.

Ease of Installation

When considering ease of installation, coarse-thread drywall screws are generally more user-friendly, especially for DIY projects. Their broader threads mean fewer rotations are needed to fully penetrate wood, making the task faster and less strenuous. Conversely, fine-thread screws often demand more effort and precision, particularly in metal applications where pre-drilling might be required. This added complexity can increase the time necessary to complete the installation project.

Compatibility with Materials

Drywall screws exhibit distinct material compatibilities based on their thread design. Coarse-thread screws are most compatible with wooden studs, offering a dependable hold and easier installation. Conversely, fine-thread screws are engineered for metal studs, ensuring a secure fit without jeopardizing structural integrity. Recognizing these compatibility traits ensures the right type of screw is selected for each specific application, optimizing performance and durability in drywall installations.

Choosing the Right Type of Drywall Screw for Your Project

Selecting the appropriate drywall screws for your project is crucial to ensuring stability and long-term durability. Understanding the differences between coarse-thread and fine-thread screws aids in making an informed decision that fits the specific needs of your project. Both types of screws have their respective benefits and limitations, and considering several factors can help in choosing the right one.

Factors to Consider When Selecting Drywall Screws

Material Being Fastened

The primary factor to consider when selecting drywall screws is the material you are fastening to. Coarse-thread screws are ideally suited for wood, offering robust holding power without requiring pre-drilling. Their wider threads provide a strong grip, making them perfect for wooden studs and frames. Conversely, fine-thread screws are designed for metal studs, facilitating a secure and snug fit. Their narrow threads reduce the risk of damaging or splitting the material, which is particularly important in metal applications.

Environmental Conditions

Environmental conditions significantly influence the selection of suitable drywall screws. In areas with high humidity or moisture exposure, it is crucial to choose screws with corrosion-resistant coatings. Coarse-thread screws are often treated with such coatings, making them ideal for outdoor projects or locations with fluctuating humidity levels. For indoor projects where aesthetics and a smooth finish are vital, fine-thread screws with a phosphate coating are more fitting, providing long-term durability without affecting the appearance of the drywalled surface.

Load-Bearing Requirements

Another key factor to consider is the load-bearing requirements of your project. Coarse-thread drywall screws provide superior holding power in wood, which is important for projects requiring a strong, secure connection. Fine-thread screws, while offering good holding power in metal, may not be sufficient for heavy load-bearing requirements in wooden structures. Evaluating the weight and stress factors that the drywall will endure helps determine which type of screw offers the necessary strength and stability.

Tips for Effective Use of Each Type of Screw

Using the correct screw type effectively ensures a successful and durable installation. Here are some practical tips to maximize the benefits of both coarse-thread and fine-thread drywall screws:

- For coarse-thread screws, ensure that you are applying consistent pressure when driving the screw into wood. This helps prevent the wood from splitting and maintains the integrity of the material. Additionally, using an appropriate power drill with the right torque settings can make the installation process smoother and faster.

- When dealing with fine-thread screws, drilling pilot holes in metal studs beforehand can greatly decrease installation time and enhance precision. This procedure ensures the screw is fastened securely without harming the metal stud. Opting for fine-thread screws with a self-tapping point can make the task even simpler, providing neat and accurate penetration.

- Always check for the appropriate length of drywall screws based on the thickness of the drywall and the material being attached. Using screws that are too long can create unnecessary protrusions, while screws that are too short may not provide adequate holding power.

- Finally, consider the finish of your project. If a smooth and aesthetically pleasing surface is critical, fine-thread screws are preferable, as they are less likely to cause bulging or surface irregularities.

By comprehensively evaluating these factors and tips, you can ensure the effective use of drywall screws, leading to a secure, durable, and visually appealing finish in your construction or renovation project.

Qewitco Fasteners Co., Ltd. stands out as a premier supplier in this domain, offering a diverse range of high-quality fasteners and fixings that cater to various industrial needs. Qewitco’s competitive product range includes fasteners of general grade, high grade, and those made from brass/copper, stainless steel, aluminum, and various alloys. The provision of test certificates, coupled with rigorous professional quality control and traceability, underscores the company’s unwavering commitment to excellence.